-

Guaranteed Fitment

Always the correct part

-

In-House Experts

We know our products

-

Added Value

FREE in house engineering and design assistance

-

Wordwide Delivery

Free shipping on all Harrington orders over 500LBS

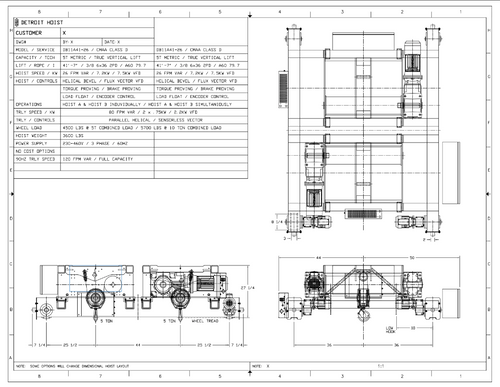

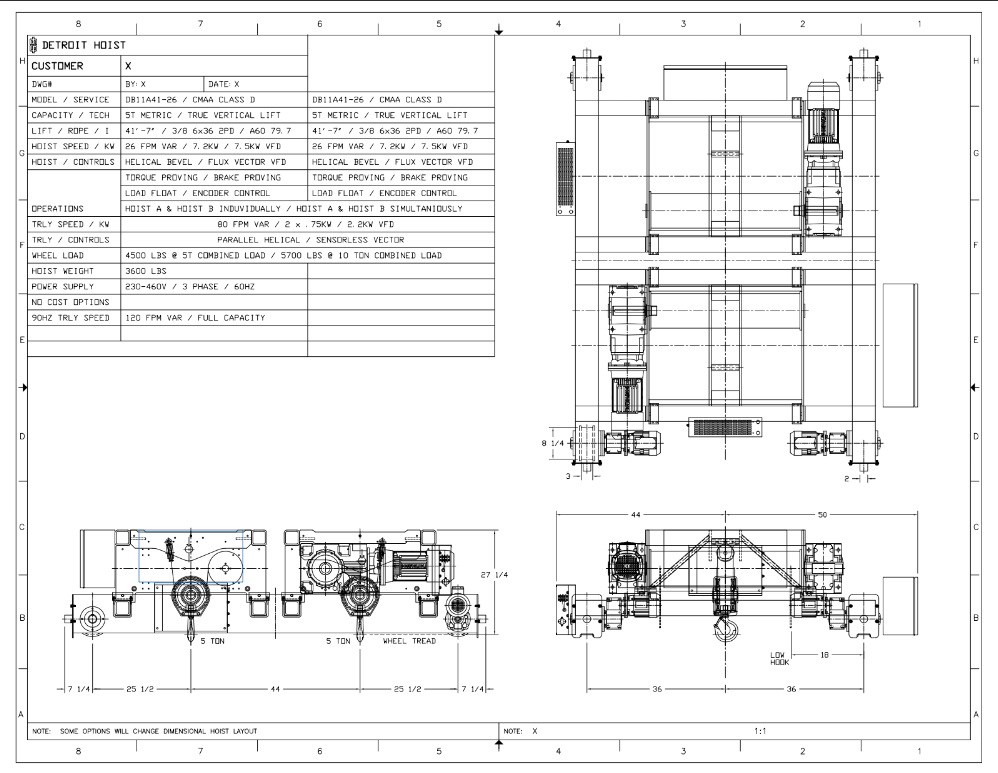

Top Running Double Girder Main / Auxiliary, Capacity: 5.50 Ton / 5.50 Ton, Hoist Lift Speed: 26.00 FPM Max / 26.00 FPM Max, Trolley Speed: 80.00 FPM Max, Trolley Gauge: 72.0000", DB11A41-26-DB11A41-26, Detroit

Top Running Double Girder Main / Auxiliary, Capacity: 5.50 Ton / 5.50 Ton, Hoist Lift Speed: 26.00 FPM Max / 26.00 FPM Max, Trolley Speed: 80.00 FPM Max, Trolley Gauge: 72.0000", DB11A41-26-DB11A41-26, Detroit

The DB11A41-26-DB11A41-26 is an exceptional top-running double girder crane, engineered specifically for demanding industrial environments. With its versatile main and auxiliary configurations, this crane promises superior performance in indoor settings where efficient material handling is paramount.

Boasting a robust capacity of 5.50 tons for both configurations, the DB11A41-26-DB11A41-26 delivers reliable lifting capabilities to maneuver medium-sized loads seamlessly across various industrial applications. Its innovative design incorporates a 2-part reeving system offering a substantial lift height of 41 feet and 7 inches, ensuring ample vertical reach for even the most challenging tasks.

- Hoist Lift Speed: Achieve rapid vertical movement with a maximum hoist lift speed of 26.00 feet per minute, significantly enhancing productivity and reducing handling times.

- Powerful Hoist Motor: Equipped with a 7.5 kW motor for both the main and auxiliary hoists, ensuring the power needed for efficient load handling.

- Advanced Hoist Control: Utilize closed-loop vector Variable Frequency Drive (VFD) technology for precise control over speed and torque, ensuring smooth load handling in diverse operating conditions.

- Trolley Speed: Maximize operational efficiency with a trolley system that operates at an impressive speed of 80.00 feet per minute, streamlining horizontal load movement along the crane span.

- Synchronized Trolley Motors: Each configuration features two 0.75 kW trolley motors, providing efficient and synchronized movement, enabling accurate load positioning.

- Seamless Trolley Control: The sensorless vector VFD control system ensures smooth acceleration and deceleration, enhancing load maneuverability.

- Dependable Power Supply: Operating on a standard 460VAC, 3-phase, 60Hz electric power supply for compatibility with common industrial electrical systems.

- CMAA Class Compliance: Specifically designed for CMAA Class D specifications, suitable for indoor service, this crane offers exceptional reliability in varying atmospheric conditions.

- Generous Trolley Gauge: With a trolley gauge of 72.0000 inches, maneuvering loads without obstruction is effortless, further enhancing the practical utilization of your workspace.

- Robust Structural Design: Weighing approximately 3600.00 lbs, each configuration is built to provide a sturdy and stable structure for safe, reliable operation during material handling tasks.

The DB11A41-26-DB11A41-26 crane exemplifies quality, efficiency, and reliability in material handling applications. Invest in this double girder main and auxiliary crane, and experience the culmination of advanced engineering and unparalleled performance.