-

Guaranteed Fitment

Always the correct part

-

In-House Experts

We know our products

-

Added Value

FREE in house engineering and design assistance

-

Wordwide Delivery

Free shipping on all Harrington orders over 500LBS

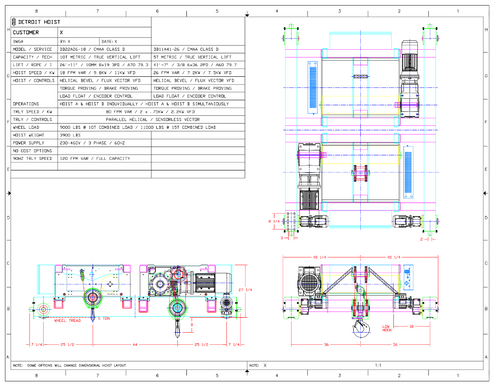

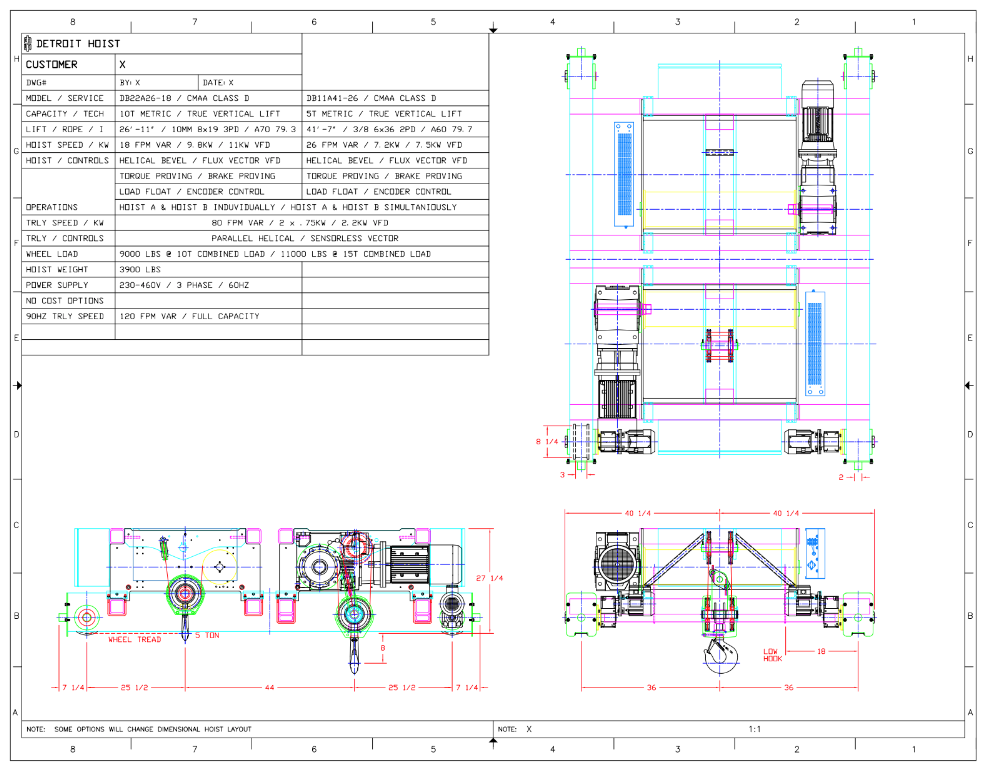

Top Running Double Girder Main / Auxiliary, Capacity: 11.00 Ton / 5.50 Ton, Hoist Lift Speed: 18.00 FPM Max / 26.00 FPM Max, Trolley Speed: 80.00 FPM Max, Trolley Gauge: 72.0000", DB22A26-18-DB11A41-26, Detroit

Top Running Double Girder Main / Auxiliary, Capacity: 11.00 Ton / 5.50 Ton, Hoist Lift Speed: 18.00 FPM Max / 26.00 FPM Max, Trolley Speed: 80.00 FPM Max, Trolley Gauge: 72.0000", DB22A26-18-DB11A41-26, Detroit

The DB22A26-18-DB11A41-26 is the pinnacle of industrial material handling, engineered as a top-running double girder crane with both main and auxiliary configurations, offering unmatched versatility and efficiency for demanding indoor applications. With robust lift capacities of 11.00 tons for the main and 5.50 tons for the auxiliary, this crane is meticulously designed to accommodate a diverse range of load sizes, ensuring optimum productivity within your workspace.

This advanced crane features a sophisticated reeving system that elevates your lifting capabilities to new heights—literally. The main configuration includes a 3-part reeving system with a lift height of 26 feet and 11 inches, adeptly handling heavy loads. In contrast, the auxiliary hoist boasts a 2-part reeving system, allowing a remarkable lift height of 41 feet and 7 inches for efficiency in elevated tasks.

- Maximum hoist lift speeds of 18.00 FPM for the main and 26.00 FPM for the auxiliary, ensuring optimal control during lifting operations.

- Powerful hoist motors: 10.4 kW for the main configuration and 7.5 kW for the auxiliary for superior performance and reliability.

- Closed-loop vector Variable Frequency Drive (VFD) control for precision in speed and torque manipulation.

- A trolley speed of 80.00 FPM, facilitating swift horizontal movement of loads across the work area.

- Synchronized dual trolley motors (0.75 kW each) for enhanced positioning accuracy during operation.

- Sensorless vector VFD control for the trolley system, enabling smooth acceleration and deceleration.

- Standard electric power supply of 460VAC, 3-phase, 60Hz, ensuring reliability and compatibility with industrial systems.

- Engineered to comply with CMAA Class specifications for indoor use, boasting durability in atmosphere class D conditions.

- A generous trolley gauge of 72.0000 inches for ample load movement clearance.

- Robust construction with an approximate weight of 3900 lbs, ensuring stability during heavy-duty tasks.

- UL508A c UL us listed industrial control panel for safe operation.

The innovative design of the DB22A26-18-DB11A41-26 crane makes it an exceptional choice for industries that demand reliability and high performance. This crane is not only about lifting but is a vital component in streamlining your material handling operations. Experience unparalleled efficiency and precision in your industrial applications today with the DB22A26-18-DB11A41-26 top-running double girder crane.