-

Guaranteed Fitment

Always the correct part

-

In-House Experts

We know our products

-

Added Value

FREE in house engineering and design assistance

-

Wordwide Delivery

Free shipping on all Harrington orders over 500LBS

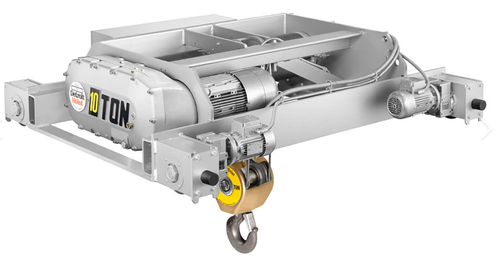

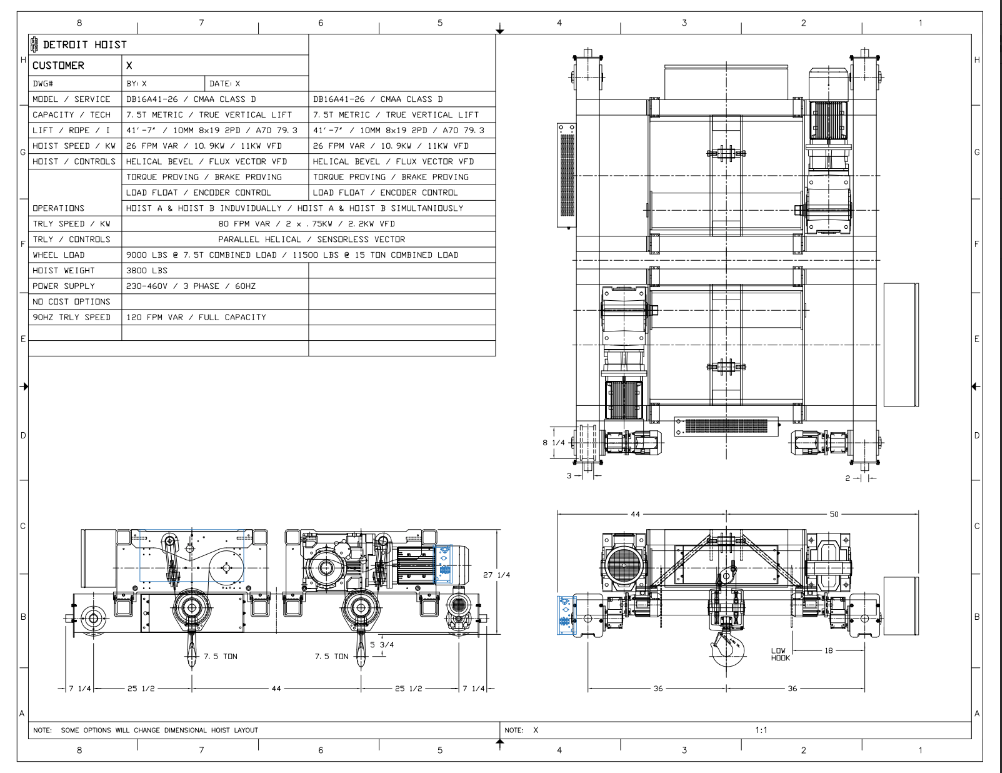

Top Running Double Girder Main / Auxiliary, Capacity: 8.25 Ton / 8.25 Ton, Hoist Lift Speed: 26.00 FPM Max / 26.00 FPM Max, Trolley Speed: 80.00 FPM Max, Trolley Gauge: 72.0000", DB16A41-26-DB16A41-26 Detroit

Top Running Double Girder Main / Auxiliary, Capacity: 8.25 Ton / 8.25 Ton, Hoist Lift Speed: 26.00 FPM Max / 26.00 FPM Max, Trolley Speed: 80.00 FPM Max, Trolley Gauge: 72.0000", DB16A41-26-DB16A41-26 Detroit

The DB16A41-26-DB16A41-26 Top Running Double Girder Crane is engineered for excellence in material handling, combining rigorous design with impressive functionality. Capable of effortlessly lifting up to 8.25 tons in both main and auxiliary configurations, this crane is an essential solution for various industrial environments.

Designed to meet demanding standards, the DB16A41-26-DB16A41-26 operates with a powerful hoist system that guarantees swift and precise load handling. With a hoist lift speed of 26.00 feet per minute and a maximum trolley speed of 80.00 feet per minute, this crane optimizes workflow and enhances productivity in any indoor setting.

- Main and Auxiliary hoist design for flexible operation.

- 2-part reeving system enables effective lifting height of 41 feet and 7 inches.

- Equipped with a formidable 10.4 kW hoist motor offering robust lifting performance.

- Closed-loop vector Variable Frequency Drive (VFD) control for precision load handling.

- Dual 0.75 kW trolley motors ensure synchronized movement and accuracy.

- Engineered for indoor service complying with CMAA Class D specifications.

- Robust trolley gauge of 72.0000 inches for ample clearance and effective load maneuvering.

- Constructed from premium grade graphite ductile iron wheels for durability.

- Equipped with adjustable upper and lower electronic encoder limits for enhanced safety.

- 110 VAC control voltage with an option for 24 VDC pushbutton control voltage.

Built with a weight of approximately 3800.00 lbs, the DB16A41-26-DB16A41-26 crane maintains stability even under the most challenging operational conditions. This crane's ingenious design transforms heavy-lifting tasks into seamless operations, making it an invaluable asset for any industrial workspace.