-

Guaranteed Fitment

Always the correct part

-

In-House Experts

We know our products

-

Added Value

FREE in house engineering and design assistance

-

Wordwide Delivery

Free shipping on all Harrington orders over 500LBS

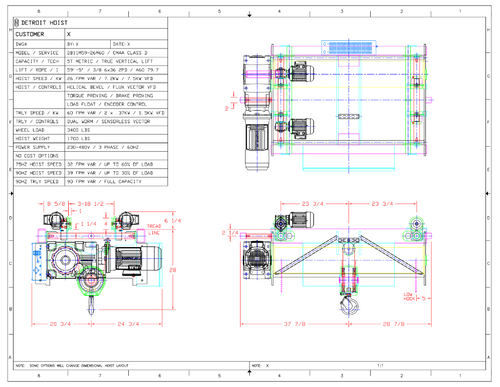

Monorail, Capacity: 5.50 Ton, Hoist Lift Speed: 26.00 FPM Max, Trolley Speed: 60.00 FPM Max, DB11M59 -26, Detroit

The Monorail DB11M59-26 is engineered for exceptional performance, boasting a remarkable lifting capacity of 5.50 tons. Designed for robust and efficient material handling in industrial environments, this hoist system ensures seamless operations, allowing businesses to optimize productivity and manage heavy loads with confidence.

Equipped with a superior 7.5 kW hoist motor, the DB11M59-26 guarantees reliable lifting capabilities, even in demanding conditions. Its sophisticated closed-loop vector Variable Frequency Drive (VFD) control maximizes precision, ensuring that every load is handled safely and efficiently. With a maximum lift speed of 26.00 feet per minute and a trolley speed reaching 60.00 feet per minute, this system significantly reduces cycle times without compromising operational safety.

- Heavy-duty capacity of 5.50 tons, ideal for industrial applications.

- Impressive lift height of 59 feet and 5 inches utilizing a 2-part reeving system.

- Fast hoist lift speed of 26.00 FPM for quick vertical movement of loads.

- Powerful hoist motor (7.5 kW) ensuring consistent performance under load.

- Precision control through closed-loop vector VFD technology for safety-enhanced operation.

- Trolley speed up to 60.00 FPM, achieving rapid horizontal movement of materials.

- Two .37 kW trolley motors for reliable lateral load movement and control.

- Sensorless vector VFD control allowing for smooth acceleration and deceleration.

- Compliant with CMAA Class D standards, robust for various atmospheric conditions.

- Durable construction weighing approximately 1700 lbs, balancing strength with manageability.

Designed for versatility, the DB11M59-26 can be easily suspended or mounted to suit various operational layouts and space requirements. The robust construction and weather-resistant features ensure that this hoist system can operate reliably in both indoor and outdoor environments. Furthermore, its compatibility with standard industrial power sources facilitates seamless integration into existing electrical systems, making it an ideal solution for businesses aiming to enhance their material handling efficiency.