-

Guaranteed Fitment

Always the correct part

-

In-House Experts

We know our products

-

Added Value

FREE in house engineering and design assistance

-

Wordwide Delivery

Free shipping on all Harrington orders over 500LBS

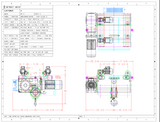

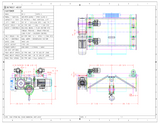

Monorail, Capacity: 3.30 Ton, Hoist Lift Speed: 26.00 FPM Max, Trolley Speed: 60.00 FPM Max, DB7M59 -26, Detroit

The Monorail DB7M59-26 stands as a premier lifting solution engineered to redefine operational efficiency and reliability in material handling. With a remarkable lifting capacity of 3.30 tons and exceptional speed, this hoist is designed to meet the demanding needs of various industrial environments while enhancing workflow productivity.

Configurable for either monorail suspension or mounting, this versatile system accommodates a range of installation needs and space constraints, making it an ideal choice for numerous applications. The dual 4-pole, AC squirrel cage inverter-rated motors ensure a true vertical lift, providing exceptional stability and control during lifting operations to heights of up to 59 feet and 5 inches.

- Impressive 3.30 tons lifting capacity, perfect for handling heavy loads with ease.

- Maximum hoist lift speed of 26.00 feet per minute (FPM) for swift and efficient load handling.

- Maximum trolley speed of 60.00 FPM, enhancing operational flexibility and movement efficiency.

- Robust 7.5 kW hoist motor delivers reliable power and torque for demanding tasks.

- Closed-loop vector Variable Frequency Drive (VFD) control ensures precise speed regulation for safe and accurate lifting.

- Two .37 kW trolley motors provide smooth and controlled movement along the monorail beam.

- Durable construction with premium-grade graphite ductile iron wheels and sheaves for extended service life.

- CMAA Class D compliant, ensuring reliable operation under standard atmospheric conditions, with weather-resistant capabilities.

- UL508A c UL listed industrial control panel with CSA Type 4, 4X enclosure for safety and durability.

- Comprehensive overload protection features with dynamic braking systems for enhanced safety.

- Adjustable upper and lower electronic encoder limits for precise operations.

- Operates seamlessly on standard electric supply of 230VAC, 3-phase, 60Hz, ensuring compatibility with most industrial setups.

This hoisting system is meticulously designed for robust performance under demanding conditions, where its high lifting speed and capacity contribute to significant productivity gains. Moreover, with a total weight of approximately 1700 lbs, it balances heavy-duty construction with manageable handling for installation. The Monorail DB7M59-26 is not just a lifting tool; it’s a pivotal asset for any facility aiming to streamline their material handling processes while ensuring safety and reliability in everyday operations.