-

Guaranteed Fitment

Always the correct part

-

In-House Experts

We know our products

-

Added Value

FREE in house engineering and design assistance

-

Wordwide Delivery

Free shipping on all Harrington orders over 500LBS

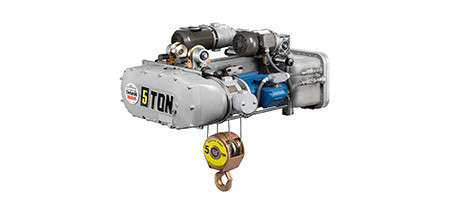

Monorail, Capacity: 3.30 Ton, Hoist Lift Speed: 26.00 FPM Max, Trolley Speed: 60.00 FPM Max, DB7M41-26, Detroit

The Monorail DB7M41-26 from Detroit is engineered for high-capacity lifting and efficient material handling, with a robust design that handles up to 3.30 tons. This state-of-the-art hoist system integrates advanced technology to streamline operations, ensuring safety and productivity in industrial environments.

With superior specifications, including a maximum hoist lift speed of 26.00 feet per minute (FPM) and a trolley speed of 60.00 FPM, the Monorail enhances workflow by enabling rapid vertical and horizontal movement of heavy loads. Its durable construction is complemented by advanced control systems that provide precision and reliability under the most demanding conditions.

- High Capacity: Designed to lift loads up to 3.30 tons, making it suitable for various industrial applications.

- Robust Motor Power: Features a 7.5 kW hoist motor, delivering powerful torque for reliable heavy-duty lifting.

- Advanced Hoist Control: Utilizes closed-loop vector Variable Frequency Drive (VFD) control, offering precise speed and torque regulation.

- Fast Trolley Movement: With a maximum trolley speed of 60.00 FPM, it optimizes horizontal load transportation, minimizing downtime.

- Durable Trolley Motors: Equipped with dual .37 kW motors for efficient load movement with dependable performance.

- Enhanced Safety Features: Includes rubber bumpers and rail sweeps to protect both the hoist and surrounding structures.

- Weather Resistant: Built to meet CMAA Class D standards, ensuring reliable operation in various atmospheric conditions.

- Dynamic Braking: Provides immediate stopping power for both hoist and trolley, enhancing user safety during operation.

- Overload Protection System: Integrated frequency drive with 3% accuracy safeguards against overloading.

- Adjustable Encoder Limits: Allows for tailored lift height control, preventing overtravel and ensuring operational precision.

- UL508A Certified Control Panel: Enclosed in a durable CSA Type 4, 4X enclosure, compliant with stringent safety standards.

- High Speed Operation: Capability to reach speeds up to 90 Hz upon request, providing versatility for specific application needs.

Investing in the Monorail DB7M41-26 is a decision that reinforces operational efficiency, safety, and reliability. This hoist system not only meets the rigorous demands of material handling but also prioritizes user safety and ease of installation. Elevate your operational capacity today with this advanced lifting solution.