-

Guaranteed Fitment

Always the correct part

-

In-House Experts

We know our products

-

Added Value

FREE in house engineering and design assistance

-

Wordwide Delivery

Free shipping on all Harrington orders over 500LBS

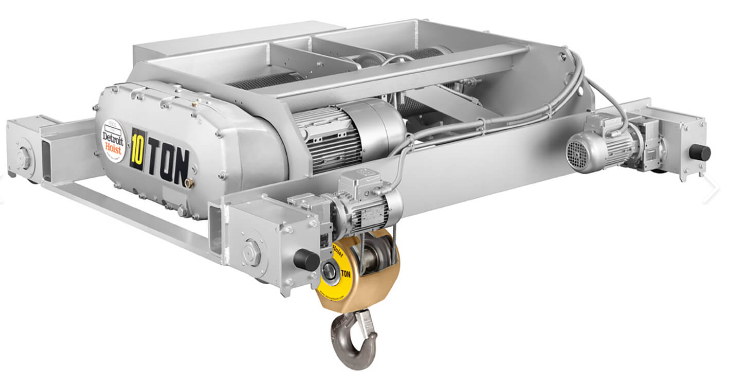

Capacity: 20.00 Ton, Reeving/Lift: 5 PD | 29' 5", Hoist Lift Speed: 12.00 FPM Max, Volt: 230VAC 3PH 60HZ+ 5%, DB40T29 12 Detroit

The Model DB40T29-12 is a top-tier lifting solution designed to meet the demanding needs of industrial environments. With a remarkable capacity of 20.00 tons, this crane offers unmatched lifting power, enabling you to handle large and heavy loads with ease and precision. Engineered for efficiency, the Model DB40T29-12 is the crucial asset your operations require to increase productivity and ensure safety.

Built with a sophisticated 5-part reeving system, this crane facilitates an impressive lift height of 29 feet and 5 inches. By optimizing mechanical advantage, the seamless elevation of hefty loads becomes effortless. With a focus on stability and efficiency, the Model DB40T29-12 delivers controlled and reliable performance throughout your lifting operations.

- Heavy-duty capacity of 20.00 tons for substantial lifting power.

- 5-part reeving system providing a lift height of 29' 5" for enhanced vertical elevation.

- Maximum hoist lift speed of 12.00 FPM for precise movement control.

- Powerful 13.4 kW hoist motor ensuring smooth load lifting and lowering operations.

- Advanced closed-loop vector VFD control for superior hoisting performance.

- Maximum trolley speed of 60.00 FPM for swift horizontal load movement.

- Two high-performance trolley motors rated at 0.86 kW each for reliable propulsion.

- Sensorless vector VFD control for responsive and efficient trolley movements.

- Compatible with standard electrical systems at 230VAC, 3-phase, and 60Hz (+5%).

- Compliant with CMAA Class D standards, suitable for various atmospheric conditions.

- Durable trolley gauge of 78.0000 inches enhancing stability during operation.

- Constructed with robust materials, weighing approximately 2600.00 lbs, ensuring durability.

- Equipped with premium-grade components including ductile iron wheels and sheaves for long-lasting performance.

The Model DB40T29-12 is not just a crane; it is a powerful lifting partner designed for operational excellence in industrial settings. With a robust build quality and advanced technology features, it guarantees optimal safety and performance, making it a valuable addition to your equipment lineup.