-

Guaranteed Fitment

Always the correct part

-

In-House Experts

We know our products

-

Added Value

FREE in house engineering and design assistance

-

Wordwide Delivery

Free shipping on all Harrington orders over 500LBS

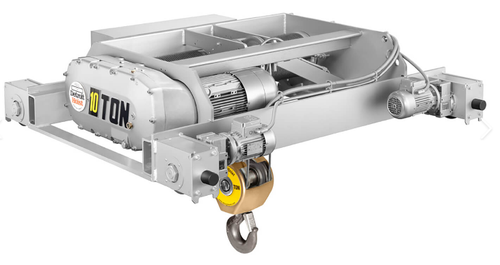

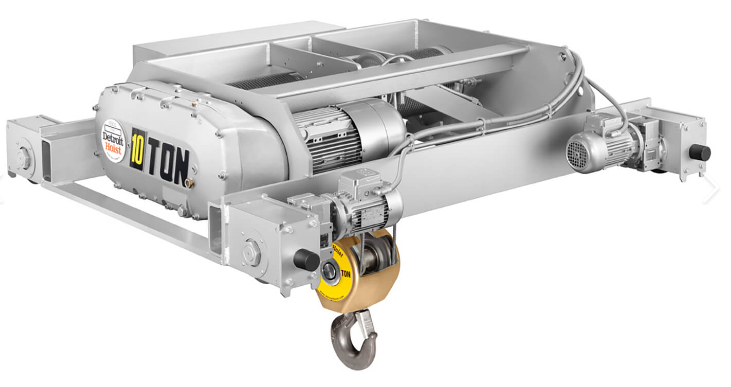

Capacity: 11.00 Ton, Reeving/Lift: 3 PD | 38' , Hoist Lift Speed: 21.00 FPM Max, Volt: 230VAC 3PH 60HZ + 5%, DB22T38 -21 Detroit

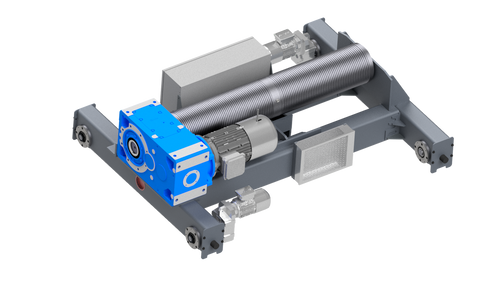

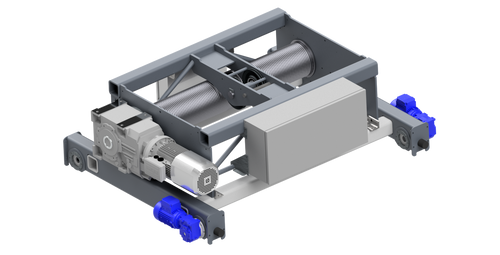

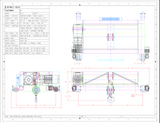

The Model DB22T38-21 sets a new standard in industrial lifting solutions with its impressive commitment to capacity and performance. Engineered for heavy-duty applications, this double girder overhead crane boasts an 11.00-ton lifting capacity, ensuring that even the most substantial loads are handled with utmost precision and safety. With this model, you can elevate your operational efficiency and confidently tackle challenging lifting tasks.

Featuring advanced engineering and robust design, this suspension or mount top-running double girder crane employs a 3-part reeving system, providing an impressive lift height of 38 feet and 8 inches. This remarkable vertical reach makes the DB22T38-21 suitable for diverse environments, such as manufacturing and construction sites, enabling seamless material handling regardless of the application. Its high-speed capabilities with a maximum hoist lift speed of 21 feet per minute further enhance productivity, minimizing downtime and increasing overall workflow efficiency.

- Type: Suspension / Mount Top Running Double Girder

- Capacity: 11.00 Ton

- Reeving/Lift: 3 PD | 38'8"

- Hoist Lift Speed: 21.00 FPM Max

- Hoist Motor: 13.4 KW, delivering exceptional performance

- Hoist Control: Closed-loop vector Variable Frequency Drive (VFD) for precise operations

- Trolley Speed: 80.00 FPM Max, ensuring quick horizontal movement

- Trolley Motor: Two motors rated at 0.55 KW for smooth operation

- Trolley Control: Sensorless vector VFD control for enhanced accuracy

- Power Supply: Electric | 230VAC-3PH-60HZ +5% for reliable integration

- CMAA Class: Compliant for indoor service, designed for atmosphere class D conditions

- Approximate Weight: 2000.00 lbs, ensuring robust construction

This crane is built with features that prioritize safety and longevity, including a 4-pole AC squirrel cage motor with brake, premium-grade graphite ductile iron wheels, and advanced overload protection systems. Its weather-resistant design and compatibility with standard electrical systems make it a versatile addition to any industrial setting. Elevate your operations with the DB22T38-21 model, a reliable partner in heavy lifting that guarantees productivity, safety, and performance.