-

Guaranteed Fitment

Always the correct part

-

In-House Experts

We know our products

-

Added Value

FREE in house engineering and design assistance

-

Wordwide Delivery

Free shipping on all Harrington orders over 500LBS

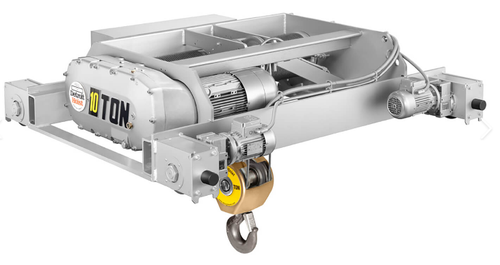

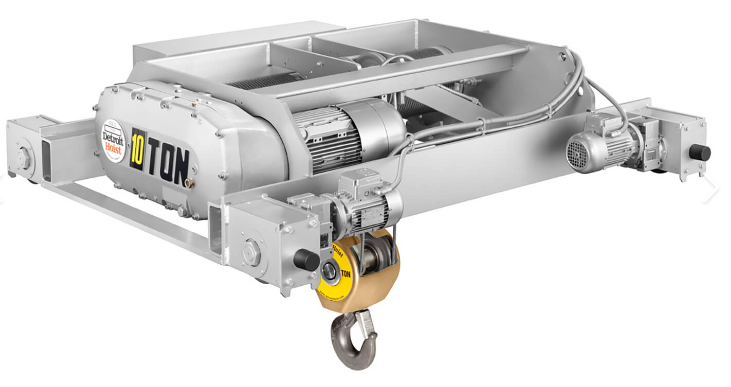

Capacity: 11.00 Ton, Reeving/Lift: 3 PD | 50' , Hoist Lift Speed: 21.00 FPM Max, Volt: 230VAC 3PH 60HZ + 5%, DB22T50 -21 Detroit

Experience unparalleled lifting capabilities with the Model DB22T50-21, a suspension/mount top running double girder hoist engineered for heavy-duty applications. Designed with a remarkable capacity of 11.00 tons, this hoist provides the strength needed for the most demanding industrial tasks, ensuring reliability, safety, and efficiency in material handling.

The Model DB22T50-21 stands out with its robust and versatile features. With a lift height of 50 feet and an advanced 3-part reeving system, this hoist is equipped to handle significant vertical lifting tasks. Additionally, a maximum hoist lift speed of 21.00 feet per minute ensures that your operations run smoothly and efficiently, minimizing downtime and boosting productivity.

- Impressive lifting capacity of 11.00 tons for heavy-duty tasks.

- 3-part reeving system providing a substantial lift height of 50' 8”.

- Fast hoist lift speed of 21.00 FPM for quick vertical movements.

- Powerful 13.4 kW hoist motor ensures exceptional torque and performance.

- Closed-loop vector Variable Frequency Drive (VFD) control for precise operations.

- Maximum trolley speed of 80.00 FPM, enhancing horizontal load handling.

- Trolley powered by dual 0.55 kW motors for smooth movement.

- Accurate trolley control with sensorless vector VFD for efficient maneuvers.

- Operates at 230VAC, 3-phase, 60Hz, ensuring integration with standard electrical systems.

- Compliant with CMAA standards for reliability in various environments.

- Weather-resistant for durability in diverse operational conditions.

- Trolley gauge of 78 inches provides stability and proper alignment.

- Approximately 2400 lbs in weight, demonstrating robust construction.

- 4-pole AC squirrel cage inverter-rated hoist motor with brake for enhanced safety.

- Dynamic braking system ensuring full control and safety during operation.

- Over-weight protection through frequency drive to 3% accuracy.

- UL508A c UL us listed industrial control panel with CSA Type 4, 4X enclosure offers safety and reliability.

- Optional control voltages available for flexibility in operation.

- Customizable hoist speed options for more versatility.

The Model DB22T50-21 is engineered for performance, featuring state-of-the-art hoist and trolley systems that ensure seamless movement and enhanced efficiency. Its durable construction, advanced control mechanisms, and robust safety features make it an ideal choice for a wide range of industrial applications. Investing in the Model DB22T50-21 means securing your operations with a hoist that is built to last and perform beyond expectations.