-

Guaranteed Fitment

Always the correct part

-

In-House Experts

We know our products

-

Added Value

FREE in house engineering and design assistance

-

Wordwide Delivery

Free shipping on all Harrington orders over 500LBS

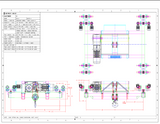

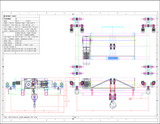

UNDER RUNNING DOUBLE GIRDER, Capacity: 5.50 Ton, Hoist Lift Speed: 26.00 FPM Max, Hoist Control: VFD, Trolley Speed: 80.00 FPM Max, Trolley Control: VFD, Power Supply: 230VAC-3PH-60HZ, Trolley Gauge: 84.0000, DB11U41- 26, DETROIT

UNDER RUNNING DOUBLE GIRDER, Capacity: 5.50 Ton, Hoist Lift Speed: 26.00 FPM Max, Hoist Control: VFD, Trolley Speed: 80.00 FPM Max, Trolley Control: VFD, Power Supply: 230VAC-3PH-60HZ, Trolley Gauge: 84.0000, DB11U41- 26, DETROIT

The UNDER RUNNING DOUBLE GIRDER Model DB11U41-26 is the epitome of robust engineering, designed to deliver unparalleled performance in moderate lifting tasks. With an impressive capacity of 5.50 tons, this crane is meticulously crafted to ensure reliability and efficiency, making it an essential asset in various industrial environments where precision lifting is critical.

Equipped with a dual-part reeving system, this crane achieves a lift height of 41 feet and 7 inches, allowing for efficient and smooth vertical movements of loads. The advanced engineering behind the Model DB11U41-26 ensures that your lifting operations are not only swift but also safe, significantly enhancing productivity across applications.

- Capacity: 5.50 tons, ideal for moderate lifting tasks.

- Hoist Lift Speed: Maximum of 26.00 FPM for efficient vertical lifting operations.

- Hoist Motor: 7.5 kW, ensuring smooth and controlled operation.

- Hoist Control: Closed-loop vector VFD for optimal performance and safety.

- Trolley Speed: Maximum of 80.00 FPM for rapid horizontal load movement.

- Trolley Motor: Equipped with 4 motors rated at 0.3 kW for reliable propulsion.

- Trolley Control: Sensorless vector VFD for precision and efficiency in trolley movements.

- Power Supply: Standard 230VAC-3PH-60HZ, ensuring compatibility with most electrical setups.

- CMAA Class: Compliant and suitable for indoor service in atmosphere class D.

- Trolley Gauge: 84.0000 inches for enhanced stability during operation.

- Approximate Weight: 2400.00 lbs, designed for durability and stability.

The Model DB11U41-26 crane stands out not only for its advanced features but also for its durability, constructed from the highest quality materials to withstand various operational challenges. Its clever design integrates features such as a 4-pole AC squirrel cage motor, premium grade graphite ductile iron wheels, and advanced braking systems that prevent motor fatigue while providing precise control.

For organizations looking to optimize their material handling processes, the UNDER RUNNING DOUBLE GIRDER Model DB11U41-26 is a definitive choice that combines performance, safety, and operational efficiency. Elevate your lifting capabilities with this outstanding crane that sets a new standard in heavy lifting technology.