-

Guaranteed Fitment

Always the correct part

-

In-House Experts

We know our products

-

Added Value

FREE in house engineering and design assistance

-

Wordwide Delivery

Free shipping on all Harrington orders over 500LBS

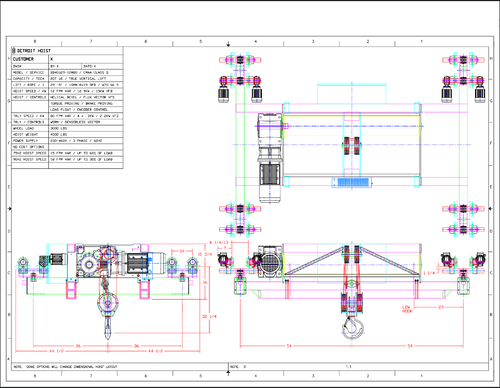

UNDER RUNNING DOUBLE GIRDER, Capacity: 20.00 Ton, Hoist Lift Speed: 12.00 FPM Max, Hoist Control: VFD, Trolley Speed: 80.00 FPM Max, Trolley Control: VFD, Power Supply: 230VAC-3PH-60HZ, Trolley Gauge: 108.0000, DB40U29- 12, DETROIT

UNDER RUNNING DOUBLE GIRDER, Capacity: 20.00 Ton, Hoist Lift Speed: 12.00 FPM Max, Hoist Control: VFD, Trolley Speed: 80.00 FPM Max, Trolley Control: VFD, Power Supply: 230VAC-3PH-60HZ, Trolley Gauge: 108.0000, DB40U29- 12, DETROIT

The DB40U29-12 Under Running Double Girder crane is designed for heavy-duty industrial applications, offering unparalleled performance in material handling solutions. With a powerful capacity of 20.00 tons, this crane is engineered to meet the rigorous demands of today's industrial environments, ensuring optimal efficiency and reliability.

This advanced crane system features a robust 5-part reeving mechanism that provides an impressive lifting height of 29 feet and 5 inches. The controlled hoist lift speed of 12.00 feet per minute guarantees precision during material handling, while enhancing workplace safety. Coupled with a formidable 13.4 kW motor, the hoist operates consistently, providing steady lifting capabilities even under substantial loads.

- Hoist Control: Equipped with advanced closed-loop vector Variable Frequency Drive (VFD) technology for precise speed and torque management.

- Trolley Performance: Achieves a swift maximum speed of 80.00 feet per minute, facilitating quick load movements across the crane span.

- Trolley Control: Features a highly efficient sensorless vector VFD control system allowing for smooth, accurate load positioning.

- Standard Power Supply: Operates seamlessly on a 230VAC, 3-phase, 60Hz power supply, compatible with most industrial setups.

- Durability: Designed to comply with CMAA Class specifications for indoor use, ensuring robust performance in atmosphere class D conditions.

- Trolley Gauge: With a generous gauge of 108.0000 inches, ample clearance is provided for efficient load movement without obstructions.

- Model Weight: Approximately 4000.00 lbs, delivering stability and dependability during operation.

- Premium Components: Features four inverter-rated motors, along with high-quality ductile iron wheels and sheaves for enhanced durability.

- Dynamic Braking System: Includes functionalities for dynamic braking and motor overload protection through sophisticated frequency drives.

- High Performance Hoist Operation: The hoist includes a closed-loop flux vector drive, 100% dynamic braking, and precise control without motor brake fatigue.

Engineered for precision, efficiency, and reliability, the DB40U29-12 Under Running Double Girder crane is the ideal choice for businesses aiming to streamline their material handling processes. Trust in the unmatched performance and safety features of this crane to elevate your industrial operations.