-

Guaranteed Fitment

Always the correct part

-

In-House Experts

We know our products

-

Added Value

FREE in house engineering and design assistance

-

Wordwide Delivery

Free shipping on all Harrington orders over 500LBS

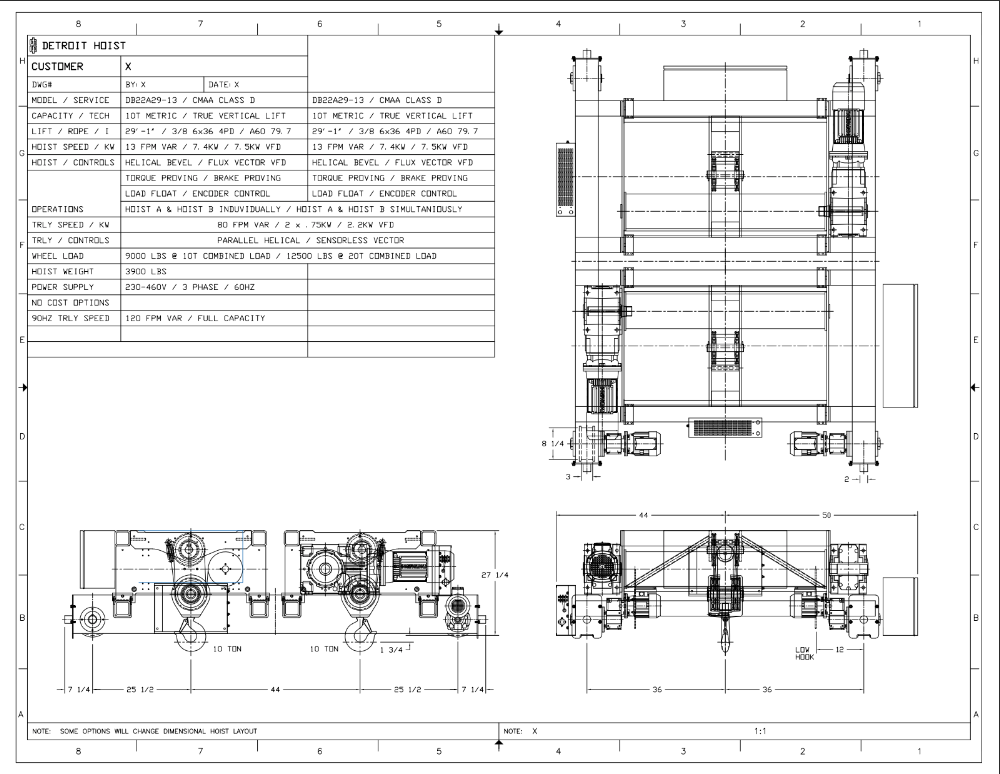

Top Running Double Girder Main / Auxiliary, Capacity: 11.00 Ton / 11.00 Ton, Hoist Lift Speed: 13.00 FPM Max / 13.00 FPM Max, Trolley Speed: 80.00 FPM Max, Trolley Gauge: 72.0000", DB22A29-13-DB22A29-13, Detroit

Top Running Double Girder Main / Auxiliary, Capacity: 11.00 Ton / 11.00 Ton, Hoist Lift Speed: 13.00 FPM Max / 13.00 FPM Max, Trolley Speed: 80.00 FPM Max, Trolley Gauge: 72.0000", DB22A29-13-DB22A29-13, Detroit

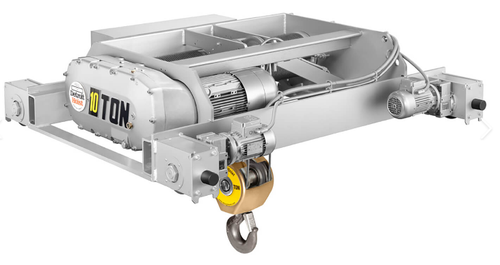

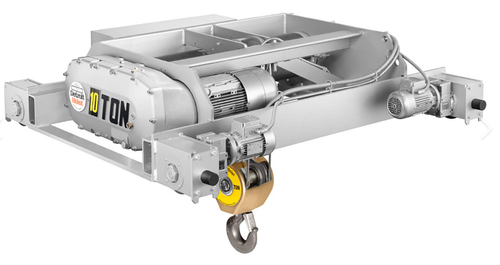

Engineered for excellence, the Top Running Double Girder Main/Auxiliary Crane, model DB22A29-13-DB22A29-13, delivers unparalleled performance in indoor industrial applications. With a robust capacity of 11.00 tons for both main and auxiliary setups, this crane is designed to handle heavy loads efficiently and safely.

The crane features advanced technologies that promote reliable and precise material handling. Equipped with dual 4-part reeving systems, both configurations facilitate a lift height of 29 feet and 1 inch, ensuring superior vertical movement capabilities. The hoist operates at a maximum lift speed of 13.00 feet per minute, allowing for controlled, effective lifting operations.

- Dual configuration capacity of 11.00 tons for versatile material handling.

- Maximum hoist lift speed of 13.00 FPM for agile load management.

- Synchronized dual 0.75 kW trolley motors for precise crane maneuverability.

- Trolley speed of 80.00 FPM max enhances horizontal load movement efficiency.

- Standard electric power supply of 460VAC, 3-phase, 60Hz ensures compatibility with industrial systems.

- CMAA Class D specifications for high-performance operation in tough environments.

- Robust trolley gauge of 72 inches providing ample clearance for seamless load transit.

- Approximate weight of 3900 lbs for a stable operational footprint.

- Closed-loop vector Variable Frequency Drive (VFD) control for enhanced precision in load handling.

- Dynamic braking and over-weight protection mechanisms for maximum safety.

- UL508A c UL us listed industrial control panel ensures regulatory compliance.

The DB22A29-13-DB22A29-13 crane is meticulously crafted for durability with features like premium grade graphite ductile iron wheels and sheaves, and includes safety features like rubber bumpers and rail sweeps to minimize wear. The hoist system boasts high efficiency with true vertical lift capabilities, dynamic braking, and motor overload protection via frequency drives, ensuring optimal performance at all times.

This crane not only streamlines your material handling processes but also enhances safety and operator confidence through its advanced control features and fail-safes. Invest in the Top Running Double Girder Crane for unmatched industrial lifting power and performance.