-

Guaranteed Fitment

Always the correct part

-

In-House Experts

We know our products

-

Added Value

FREE in house engineering and design assistance

-

Wordwide Delivery

Free shipping on all Harrington orders over 500LBS

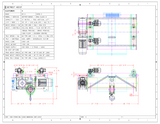

Monorail, Capacity: 8.25 Ton, Hoist Lift Speed: 26.00 FPM Max, Trolley Speed: 80.00 FPM Max, DB16M59 -26, Detroit

The Model DB16M59-26 Monorail System is engineered for industrial applications demanding high lifting capacities and swift maneuverability. With a remarkable 8.25-ton capacity and advanced hoist lift speeds up to 26.00 feet per minute, this hoist system guarantees operational efficiency while maintaining safety and reliability in heavy-duty lifting operations.

Designed for versatility, the DB16M59-26 accommodates various installation requirements with its monorail suspension and mounting configurations. Perfectly suited for environments where space and configuration may vary, it ensures substantial vertical reach with an impressive lift height of 59 feet and 5 inches, making it ideal for handling tall or bulk materials.

- 8.25 Ton lifting capacity, perfect for heavy loads

- Hoist lift speed up to 26.00 FPM for swift vertical movement

- High-torque 10.4 kW hoist motor for reliable performance

- Closed-loop vector VFD control for enhanced speed and torque regulation

- Maximum trolley speed of 80.00 FPM for efficient horizontal load handling

- Sensorless vector VFD control for smooth trolley operation

- Compatible with 230VAC, 3-phase, 60Hz power supply

- Meets CMAA Class D standards for operational reliability

- Weather-resistant design suitable for outdoor use

- Approximate weight of 1800 lbs ensuring a balance between robustness and ease of installation

- Premium-grade graphite ductile iron wheels for durability and performance

- UL508A c UL listed industrial control panel with CSA Type 4, 4X enclosure

- Dynamic braking and overload protection for enhanced safety

This monorail hoist system is crafted with a focus on operational efficiency and safety. Its innovative closed-loop flux vector drive technology ensures precise positioning and control without motor brake fatigue. Customizations are available for hoist speed, allowing for increased productivity tailored to specific operational needs. Invest in the DB16M59-26 Monorail System for unparalleled performance in your material handling applications.