-

Guaranteed Fitment

Always the correct part

-

In-House Experts

We know our products

-

Added Value

FREE in house engineering and design assistance

-

Wordwide Delivery

Free shipping on all Harrington orders over 500LBS

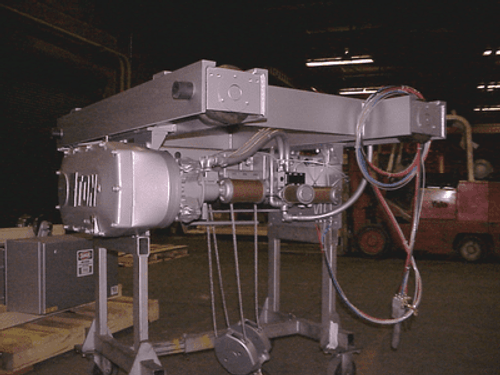

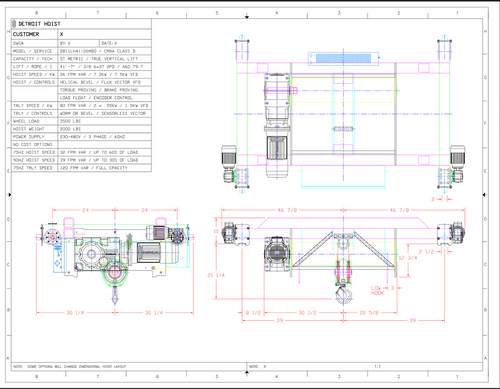

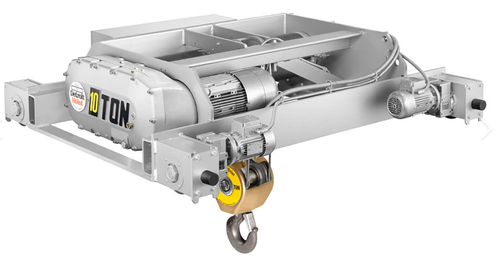

Top Running Double Girder Low Profile, Capacity: 5.50 Ton, Hoist Lift Speed: 26.00 FPM Max, Trolley Speed: 80.00 FPM Max, Trolley Gauge: 78.0000", DB11LH41-26, Detroit

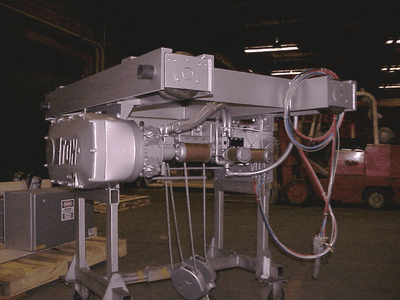

The DB11LH41-26 Top Running Double Girder Low Profile crane leads the market in reliability and efficiency, boasting a capacity of 5.50 tons and a robust design that optimizes space and performance. Perfect for various industrial applications, this crane is engineered to handle medium-sized loads with exceptional ease and safety.

Designed for seamless operation, this crane features a state-of-the-art 2-part line reeving system that allows for lifting heights of up to 41 feet and 7 inches. This innovative configuration enhances the crane's lifting capabilities while ensuring maximum stability and control during operation.

- Hoist Lift Speed: Achieve quick and efficient vertical movement with a hoist lift speed of 26 feet per minute, allowing for precise material positioning.

- Hoist Motor: Powered by a 7.5 kW motor, it guarantees reliable performance with smooth and controlled lifting operations for heavier loads.

- Hoist Control: Utilize closed-loop vector Variable Frequency Drive (VFD) control for enhanced responsiveness and safety, giving operators the ability to adjust lifting speeds and directions.

- Trolley Speed: With an impressive trolley speed of 80 feet per minute, this system promises swift horizontal movement along the runway beams, thereby increasing productivity.

- Trolley Motor: Dual motors rated at 0.55 kW each ensure balanced and consistent performance, making material handling efficient and reliable.

- Trolley Control: The sensorless vector VFD control system allows for precise trolley speed adjustments, improving operational efficiency.

- Power Supply: Designed for electric operation, it is compatible with a standard power supply of 230VAC, 3-phase, 60Hz, making installation straightforward.

- CMAA Class: Rated as CMAA Class D, this crane withstands various environmental conditions, making it suitable for outdoor use.

- Trolley Gauge: Featuring a trolley gauge of 78 inches for improved trolley movement and stability.

- Approximate Weight: At 2000 lbs, this crane is lightweight yet sturdy, facilitating easy installation while ensuring robust performance.

- Safety Features: Equipped with over-weight protection and dynamic braking to ensure ultimate safety during operation.

- Durability: Built with premium-grade materials, it includes rubber bumpers and ductile iron wheels, ensuring long-lasting performance.

Incorporating advanced technology and robust engineering, the DB11LH41-26 Top Running Double Girder Low Profile crane is designed for those who demand precision, efficiency, and durability. Revolutionize your lifting operations and enhance productivity with this superior crane solution.