-

Guaranteed Fitment

Always the correct part

-

In-House Experts

We know our products

-

Added Value

FREE in house engineering and design assistance

-

Wordwide Delivery

Free shipping on all Harrington orders over 500LBS

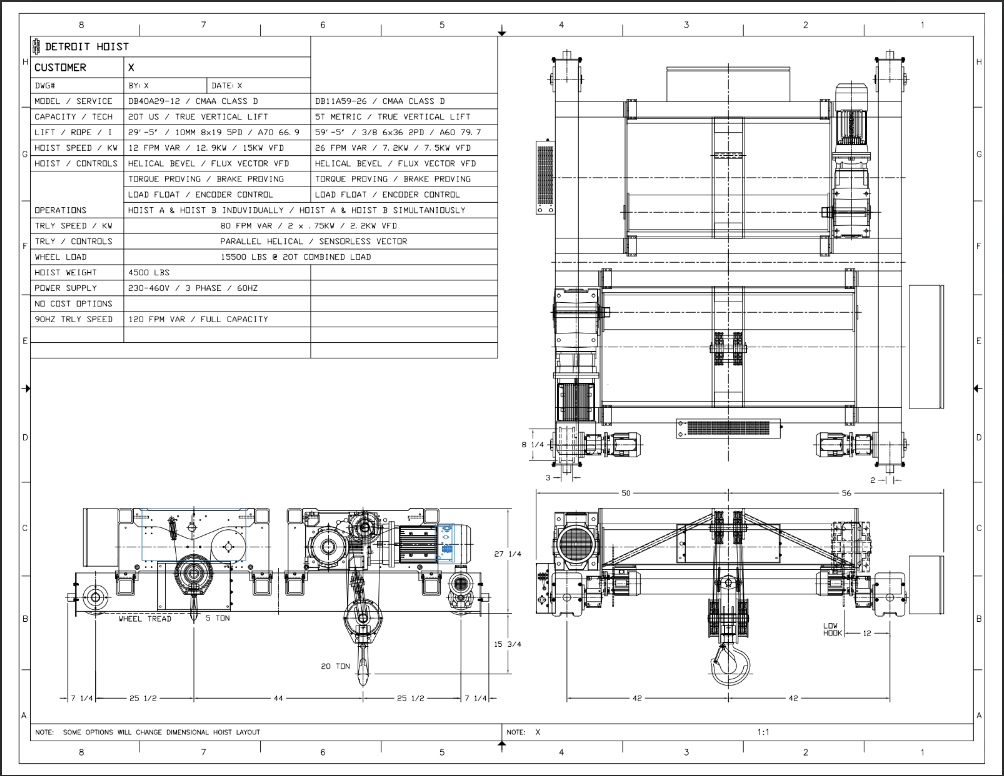

Top Running Double Girder Main / Auxiliary, Capacity: 20.00 Ton / 5.50 Ton, Hoist Lift Speed: 12.00 FPM Max / 26.00 FPM Max, Trolley Speed: 80.00 FPM Max, Trolley Gauge: 84.0000", DB40A29-12-DB11A59-26, Detroit

Top Running Double Girder Main / Auxiliary, Capacity: 20.00 Ton / 5.50 Ton, Hoist Lift Speed: 12.00 FPM Max / 26.00 FPM Max, Trolley Speed: 80.00 FPM Max, Trolley Gauge: 84.0000", DB40A29-12-DB11A59-26, Detroit

Engineered for supreme efficiency and reliability, the Top Running Double Girder Main/Auxiliary Crane rises to the challenge of demanding industrial environments with a remarkable lifting capacity and cutting-edge technology. This state-of-the-art crane offers a robust support system for both main and auxiliary components, making it an indispensable asset for heavy lifting applications.

With a powerful main hoist capacity of 20.00 tons and an auxiliary hoist capacity of 5.50 tons, this crane is designed to handle a diverse range of loads effortlessly. Its versatile reeving systems allow for impressive lift heights, ensuring it can accommodate varying lifting requirements.

- Top Running Double Girder configuration for enhanced stability and support.

- Main hoist capacity of 20.00 tons and auxiliary hoist capacity of 5.50 tons.

- 5 part line reeving for main hoist with a lift of 29'5" and 2 part line reeving for auxiliary hoist with a lift of 59'5".

- Main hoist maximum lift speed of 12.00 FPM and auxiliary hoist speed of 26.00 FPM for optimal efficiency.

- Powerful 13.4 KW motor for the main hoist and 7.5 KW for the auxiliary hoist.

- Closed-loop vector Variable Frequency Drive (VFD) control for smooth hoisting operations.

- Maximum trolley speed of 80.00 FPM for swift horizontal movement.

- Trolley motor rated at 0.75 KW ensures reliable movement along the runway beams.

- Sensorless vector VFD control for accurate trolley maneuvering and enhanced safety.

- Operates on standard electric power supply at 460VAC, 3-phase, 60Hz with tolerance of ±5%.

- CMAA Class D classification suitable for standard indoor service, ensuring operational reliability.

- Spacious trolley gauge of 84.0000 inches for smooth load positioning and maneuverability.

- Weighing approximately 4500.00 lbs, designed for structural integrity and ease of installation.

- UL508A certified control panel with NEMA 4 enclosure guaranteeing safety and compliance.

- Advanced overload and dynamic braking protection integrated within the system.

- Adjustable electronic encoder limits to enhance operational safety.

- Optional 110 VAC or 24 VDC control voltage for versatile operation.

The Top Running Double Girder Main/Auxiliary Crane stands out as a reliable and versatile lifting solution for various industrial applications. With its advanced features and robust design, it offers efficiency, safety, and superior operational control that will enhance your material handling tasks. Invest in high-quality lifting technology that delivers consistently, ensuring productivity and safety within your workspace.