-

Guaranteed Fitment

Always the correct part

-

In-House Experts

We know our products

-

Added Value

FREE in house engineering and design assistance

-

Wordwide Delivery

Free shipping on all Harrington orders over 500LBS

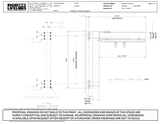

Standard Column-Mounted Swing Arm 2-Person, Arm Reach: 8'-0", Bracket Centers 4'-0", Boom Lock No, Thrust/Pull Loading: 5900, Fixed End Stops: Two at Each End, Weight: 380 lbs FA300-2-08-DST Rigid Lifelines

Standard Column-Mounted Swing Arm 2-Person, Arm Reach: 8'-0", Bracket Centers 4'-0", Boom Lock No, Thrust/Pull Loading: 5900, Fixed End Stops: Two at Each End, Weight: 380 lbs FA300-2-08-DST Rigid Lifelines

Elevate the safety and efficiency of your workspace with the Standard Column-Mounted Swing Arm by Rigid Lifelines, designed specifically for two users. With a robust construction capable of handling ±5900 pounds of thrust or pull loading, this swing arm system is your ideal solution for demanding industrial applications.

The swing arm features a generous arm reach of 8 feet and bracket centers of 4 feet, allowing versatile access across your work area. Its simple yet effective design makes it perfect for both routine tasks and complex projects requiring reliable overhead support.

- Worker Capacity: Designed for 2 users (non-passable), maximizing workflow without jeopardizing safety.

- Arm Reach: Offers an impressive reach of 8 feet, enhancing accessibility to various workstation points.

- Bracket Centers: Stable anchorage is provided by brackets positioned at 4-foot intervals, promoting weight distribution and operational safety.

- Boom Lock: Enjoy unfettered movement with no boom lock, giving you the flexibility needed in your daily operations.

- Trolleys: Features two anchor trolleys equipped with patented auto-brake technology for controlled movement and enhanced safety.

- Thrust/Pull Loading: Capable of withstanding loads up to ±5900 pounds, this swing arm is engineered for heavy-duty performance.

- Fixed End Stops: Safety is prioritized with fixed end stops at both ends of the track, preventing uncontrolled trolley movement.

- Weight: Weighs approximately 380 pounds, balancing structural integrity with ease of installation and adjustment.

- Coating: Finished with yellow industrial enamel for durability and corrosion resistance in indoor settings.

- Safety Note: The anchor trolley significantly reduces the risk of suspension trauma, ensuring optimal safety for users.

- Compliance: All components adhere to ANSI Z359, OSHA 1910, and OSHA 1926 standards, providing peace of mind regarding safety and performance.

- Customer Requirements: Customers must specify the drop length of the operating rope to ensure optimal safety and performance.

Make a wise investment in your workplace's safety and productivity with the Standard Column-Mounted Swing Arm by Rigid Lifelines. Its combination of innovative features and compliance with stringent safety standards makes it a premier choice for industries requiring reliable overhead support. Experience the quality and performance that Rigid Lifelines is known for and enhance your operational capabilities today.