Tool Balancers

Tool balancers—also known as load balancers or spring balancers—are essential for improving ergonomics, productivity, and operator safety in industrial settings. Designed to suspend and counterbalance tools, they reduce operator fatigue, prevent tool damage, and increase workplace efficiency in assembly lines, fabrication shops, and manufacturing facilities.

Key Features & Benefits:

Load Range Flexibility: Balancers are available in a variety of weight capacities, typically ranging from 0.5 lbs to 300 lbs, accommodating everything from small handheld tools to heavy-duty industrial equipment.

Zero-Gravity Tool Handling: Balancers create a near weightless feel by evenly distributing tool weight, allowing operators to maneuver tools effortlessly and maintain precise control.

Spring or Air-Powered Operation: Choose from spring balancers for light to moderate loads or air balancers for smoother vertical movement and precision positioning with heavier tools.

Improved Ergonomics & Safety: By minimizing strain on the arms, shoulders, and back, balancers help reduce the risk of repetitive motion injuries and fatigue-related errors.

Durable Construction: Built with reinforced steel housings, corrosion-resistant finishes, and enclosed springs or cylinders, balancers are designed to withstand continuous industrial use.

Integrated Safety Features: Many models include safety locks, anti-recoil mechanisms, and adjustable tension settings for customized, secure operation.

Ideal Applications:

Tool balancers are used across various industries, including automotive, aerospace, electronics, heavy manufacturing, and packaging. They’re especially effective in assembly lines where tools must be repeatedly raised and lowered or held in position for extended periods.

For operations seeking to enhance productivity, reduce tool wear, and improve worker comfort, industrial balancers offer a practical, efficient solution. Whether you're managing a high-speed assembly line or a precision repair station, tool balancers help keep your tools ready and your workforce performing at its best.

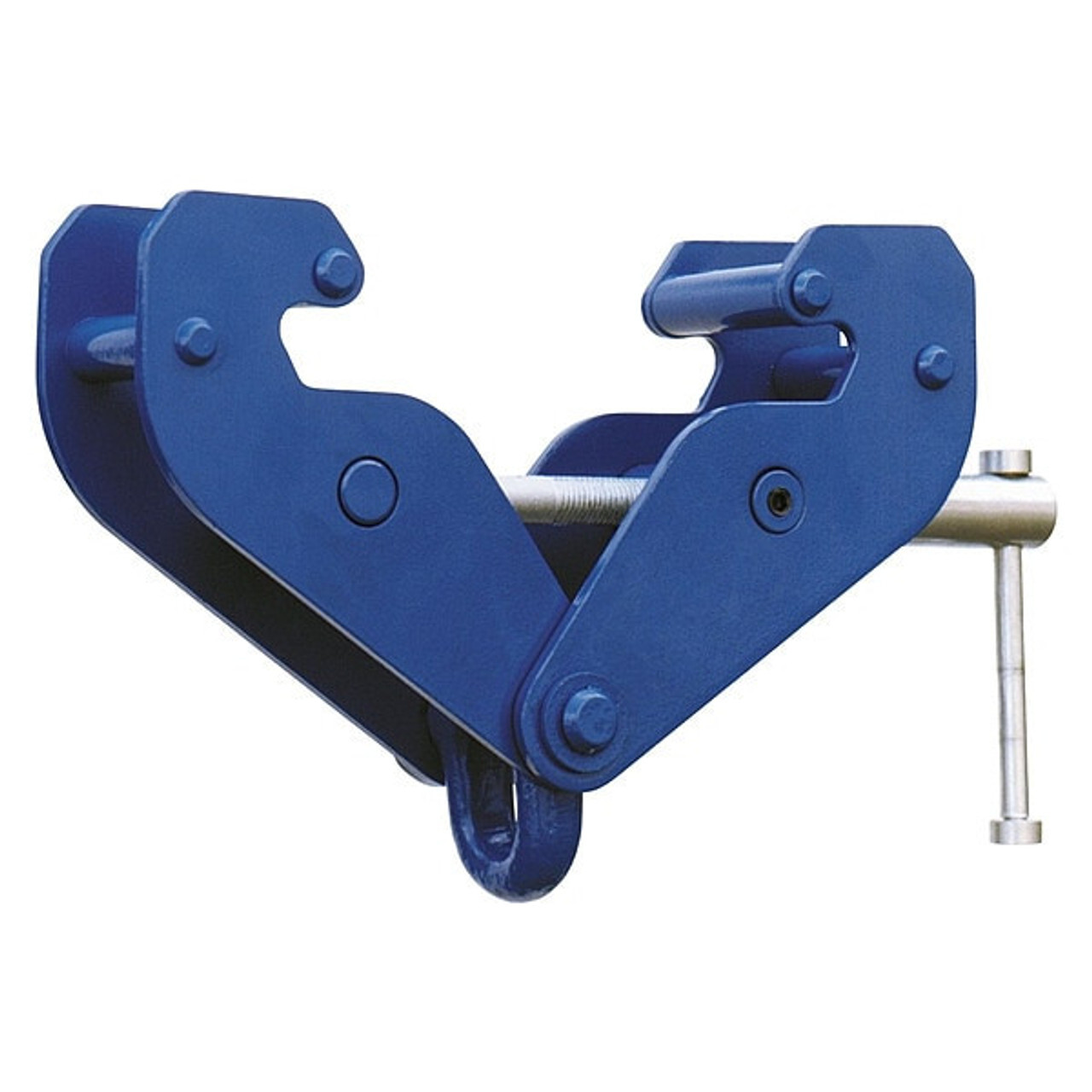

Beam clamps are essential components in the construction, rigging, and lifting industries, providing reliable and secure connections for various applications. Designed specifically to attach to I-beams and H-beams, these industrial-grade beam clamps ensure stable, overhead support for lifting heavy loads, making them absolutely indispensable when securing lifting equipment and machinery. We offer an extensive selection of the highest quality beam clamps, including robust models like the Atlas Lifting and Rigging Titon series (available in 1 Ton, 3 Ton, and 5 Ton capacities) and the heavy-duty TBC-100 with a remarkable 10 Ton capacity. All our clamps are constructed with high-quality, durable materials and rigorously engineered and tested to withstand the challenges of professional, heavy-duty operations. Their reliable design facilitates quick and easy installation, providing a tight, secure grip without compromising on safety—offering complete peace of mind whether you're lifting, securing, or supporting critical loads. With a diverse range of capacities available, you can easily select the right beam clamp tailored to your project's specific requirements, ensuring optimal performance across various environments, from busy construction sites to large warehouses. Each model is equipped with user-friendly features for seamless integration with your existing rigging systems. When choosing your next beam clamp, it's crucial to evaluate factors like the required load capacity, compatibility with your existing infrastructure, and overall ease of use. Our Atlas beam clamps are widely renowned for their proven reliability and efficiency, backed by industry-leading warranties, making them a smart, long-term investment for any professional lifting operation. Explore our comprehensive inventory of beam clamps today and safely elevate your lifting and rigging capabilities to the next level with products designed for professionals who demand the very best in strength, safety, and efficiency.

Beam clamps are essential components in the construction, rigging, and lifting industries, providing reliable and secure connections for various applications. Designed specifically to attach to I-beams and H-beams, these industrial-grade beam clamps ensure stable, overhead support for lifting heavy loads, making them absolutely indispensable when securing lifting equipment and machinery. We offer an extensive selection of the highest quality beam clamps, including robust models like the Atlas Lifting and Rigging Titon series (available in 1 Ton, 3 Ton, and 5 Ton capacities) and the heavy-duty TBC-100 with a remarkable 10 Ton capacity. All our clamps are constructed with high-quality, durable materials and rigorously engineered and tested to withstand the challenges of professional, heavy-duty operations. Their reliable design facilitates quick and easy installation, providing a tight, secure grip without compromising on safety—offering complete peace of mind whether you're lifting, securing, or supporting critical loads. With a diverse range of capacities available, you can easily select the right beam clamp tailored to your project's specific requirements, ensuring optimal performance across various environments, from busy construction sites to large warehouses. Each model is equipped with user-friendly features for seamless integration with your existing rigging systems. When choosing your next beam clamp, it's crucial to evaluate factors like the required load capacity, compatibility with your existing infrastructure, and overall ease of use. Our Atlas beam clamps are widely renowned for their proven reliability and efficiency, backed by industry-leading warranties, making them a smart, long-term investment for any professional lifting operation. Explore our comprehensive inventory of beam clamps today and safely elevate your lifting and rigging capabilities to the next level with products designed for professionals who demand the very best in strength, safety, and efficiency.