In today's industrial landscape, where efficiency and productivity are paramount, businesses require powerful and adaptable material handling solutions. The Detroit, DB11M41-26 monorail system steps up to the challenge, offering a perfect blend of capacity, speed, and versatility.

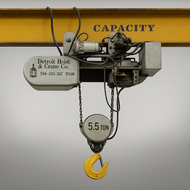

The DB11M41-26 boasts a robust lifting capacity of 5.5 tons. This makes it adept at handling a wide range of materials, from bulky machinery components and heavy building supplies to large palletized goods. This mid-range capacity provides a valuable balance for businesses that require a system capable of tackling diverse lifting tasks without the need for the immense power (and cost) of heavier-duty models.

Beyond its impressive capacity, the DB11M41-26 prioritizes operational efficiency. It features a maximum hoist lift speed of 26 feet per minute (FPM), significantly reducing lifting times and minimizing downtime. Additionally, the trolley, which carries the hoist along the monorail beam, can travel at speeds of up to 60 FPM, enabling swift horizontal movement of loads. This two-fold approach to speed guarantees a streamlined material handling process, keeping operations flowing smoothly. For a more precise understanding of the specific features and functionalities, consulting the manufacturer's documentation or contacting their sales team is recommended.

One significant advantage of monorail systems over traditional cranes is their space-saving design. The DB11M41-26 utilizes a single beam instead of multiple support structures, maximizing usable floor area. This makes it an ideal solution for facilities with limited overhead clearance or where optimizing production floor space is a priority.

The DB11M41-26 likely falls under the category of medium-duty monorail systems. This versatility makes it a perfect fit for a wide range of industrial applications, including:

- Manufacturing plants: Streamlining production lines by efficiently moving components and finished goods.

- Warehouses: Expediting the loading and unloading of palletized materials, especially for heavier items.

- Assembly lines: Precisely positioning parts for efficient assembly processes, particularly for more significant components.

- Machine shops: Lifting and maneuvering machinery components with confidence.

The DB11M41-26's ability to handle diverse loads efficiently, coupled with its space-saving design, positions it as a cost-effective and adaptable solution for a multitude of industrial needs.

Please feel free to reach out to us at 855-776-8354. Protek Crane Solutions is delighted to assist with any inquiries you may have about our product lines.