Please enter the description of the category

Please enter the description of the category

Please enter the description of the category

Please enter the description of the category

Lifting & Material Handling Accessories

The Accessories category includes essential components and add-ons designed to enhance the performance, safety, and versatility of your lifting and material handling equipment. From hoist attachments to crane components and electrical upgrades, these accessories help customize your system to meet specific operational needs.

Key Features & Benefits:

• Wide Compatibility: Accessories are designed to work with a broad range of equipment including hoists, trolleys, cranes, jibs, gantries, and festoon systems—making it easy to expand or optimize existing setups.

• Performance Enhancements: Choose from items such as load limiters, radio remote controls, variable frequency drives (VFDs), and brake kits to improve safety, control, and operational efficiency.

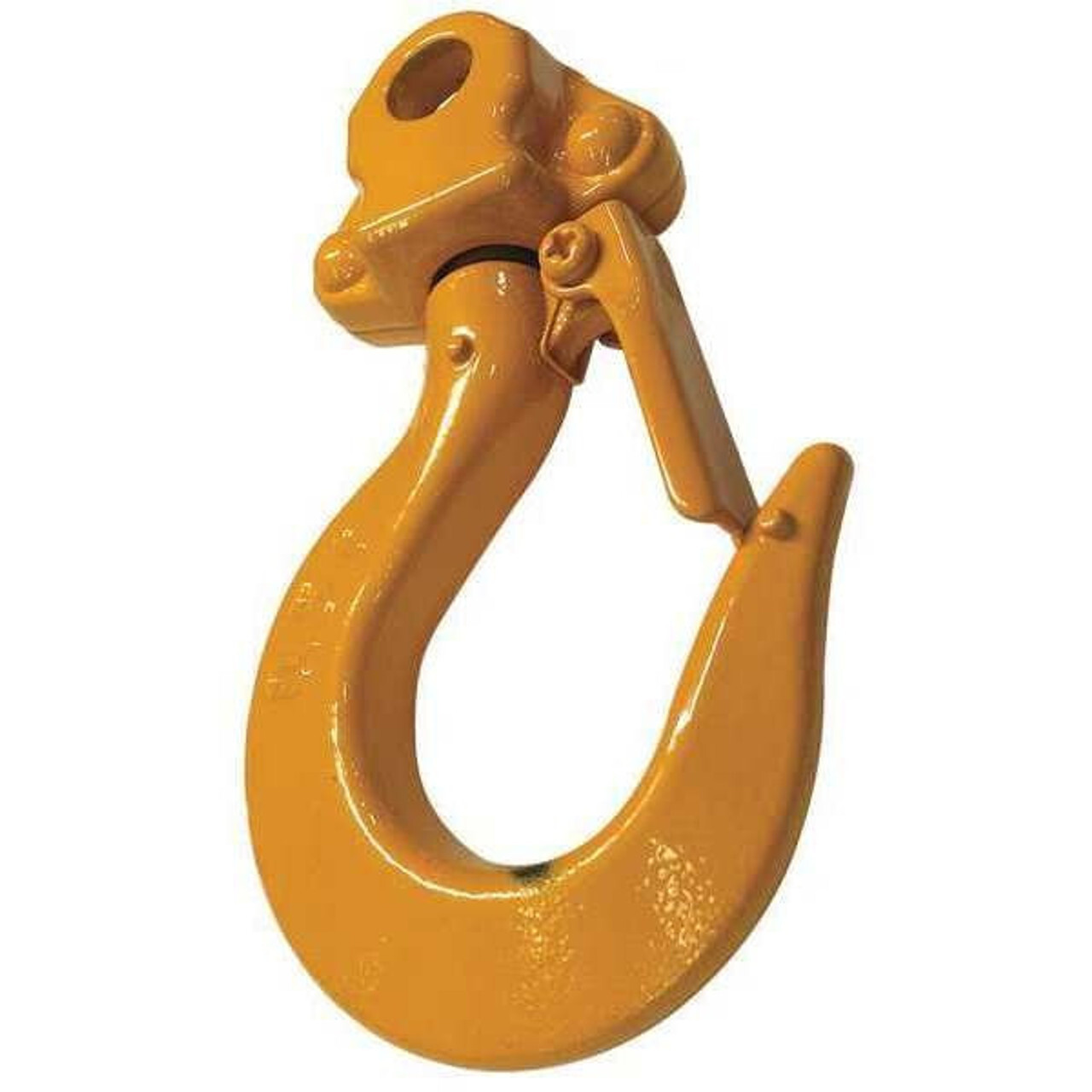

• Rigging & Lifting Support: Includes a variety of hooks, shackles, slings, lifting beams, clamps, and spreader bars to ensure secure and stable load handling across various applications.

• Electrical & Control Accessories: Upgrade your system with push button pendants, power cords, receptacles, GFCI protection, and twist-lock connectors for safer and more flexible power delivery.

• Mounting & Support Options: Browse beam clamps, brackets, adapters, and mounting kits for easy installation and reliable system integration.

• Durable Construction: All accessories are built from industrial-grade materials to withstand heavy use, harsh environments, and long-term wear.

Common Applications:

Lifting accessories are commonly used in manufacturing, maintenance, construction, warehousing, logistics, and assembly operations where adaptability, precision, and safety are essential.

Whether you're customizing a new system or upgrading an existing one, our wide selection of material handling accessories ensures you have the tools to enhance productivity and maintain safety in every lift.

Please enter the description of the category

Please enter the description of the category

Please enter the description of the category

Radio Remote Control Systems

Radio remote control systems provide a wireless solution for operating cranes, hoists, winches, and other industrial equipment with improved mobility, safety, and efficiency. These systems eliminate the limitations of pendant controls and cab-based stations, allowing operators to control machinery from a safe distance and optimal vantage point.

Key Features & Benefits:

• Wireless Freedom: With long-range radio signals, operators can control equipment from up to several hundred feet away, enhancing visibility and reducing the risk of being in hazardous zones.

• Multi-Function Capabilities: Available with single-speed or dual-speed buttons, selector switches, emergency stop functions, and programmable logic to manage multiple equipment types from one remote.

• Durable & Rugged Design: Engineered with impact-resistant enclosures, these remotes are built to withstand tough conditions, including dust, moisture, and temperature extremes.

• Failsafe Operation: Equipped with emergency stop features, auto-shutoff timers, and signal encryption, radio remotes ensure safe, secure, and interference-free communication between transmitter and receiver.

• Easy Integration: Compatible with electric hoists, bridge cranes, trolleys, conveyors, and more, most radio systems are plug-and-play or include straightforward retrofit kits for existing equipment.

• Battery-Powered Convenience: Rechargeable or replaceable battery options provide extended use with minimal maintenance.

Common Applications:

Radio remote controls are commonly used in steel mills, warehouses, construction sites, shipyards, mining operations, and automated manufacturing environments where precision and operator safety are critical.

For enhanced control, mobility, and workplace safety, radio remote control systems offer a smart, efficient upgrade to traditional wired controls—streamlining operations while keeping operators out of harm’s way.

Industrial Cable & Hose Reels

Reels are essential components for managing cables, cords, and hoses in industrial, commercial, and maintenance environments. Designed to improve safety, reduce clutter, and extend the life of cables and hoses, industrial reels provide organized storage and reliable retraction for a wide range of equipment and applications.

Key Features & Benefits:

• Spring-Driven & Motorized Options: Choose from spring retractable, manual crank, or motorized reels depending on your specific application and power needs. Spring-driven reels offer quick, automatic retraction while motorized versions are ideal for heavy-duty, high-capacity setups.

• Durable Construction: Built with powder-coated steel, aluminum, or composite housings, industrial reels are made to withstand harsh environments, including exposure to oil, water, and chemicals.

• Cable & Hose Versatility: Reels are available for managing electrical cables, air hoses, welding leads, hydraulic lines, and more—supporting various voltage, amperage, and pressure requirements.

• Mounting Flexibility: Wall, ceiling, bench, or mobile cart mounting options provide versatility for integrating reels into nearly any workspace layout.

• Safety & Efficiency: By preventing kinks, tangles, and trip hazards, reels enhance operational safety and reduce equipment downtime.

Common Applications:

Industrial reels are used in warehouses, workshops, service bays, construction sites, aviation, marine, and utility maintenance operations. Whether supplying power, air, fluids, or data, reels deliver controlled access and secure storage for hoses and cables.

For reliable cable and hose management that supports efficiency and workplace safety, industrial reels are a critical part of any well-organized facility.

Please enter the description of the category

__94128.original.jpg)